Sunflower Seed Oil Pressing: To Dehull or Not to Dehull?

01/09/26

A seemingly simple choice can greatly impact oil yield, product grade, and even the overall profitability of the sunflower oil production line.

Sunflower seeds feature a high oil content (40–50%) and a high shell ratio (30–40%). The shell acts as a structural support during pressing but can also absorb oil and affect the color of the final product.

Thus, in modern sunflower oil processing lines, whether to dehull becomes a critical decision in process design.

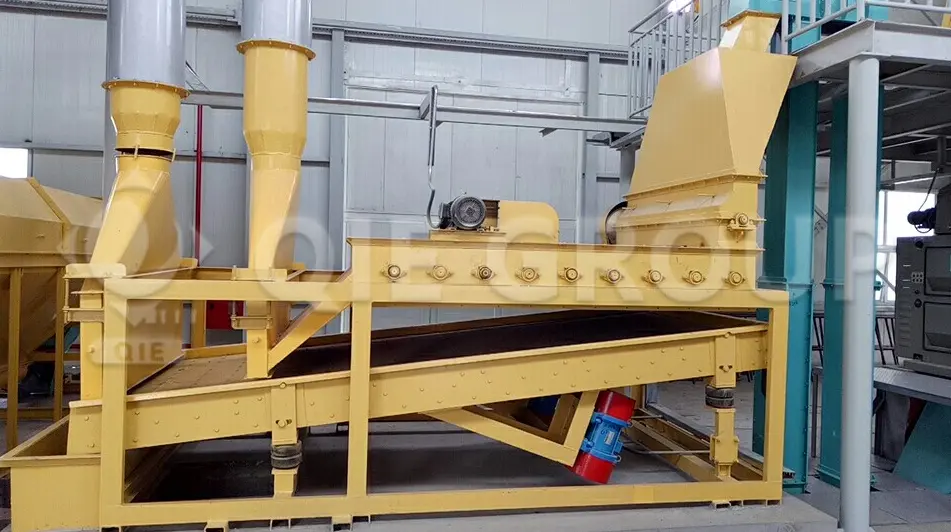

Dehulling involves cleaning, shell removal, kernel-shell separation, and conditioning before entering the screw oil press and solvent extraction process. This route is ideal for producing high-quality cooking oil with light color and delicate flavor, but it requires precise equipment matching and process control.

Skipping dehulling simplifies the process; the shells provide additional press chamber support, making it suitable for markets prioritizing economic efficiency and rich, aromatic oil.

A truly efficient sunflower oil processing solution is not about “right or wrong,” but about aligning the process route with your product positioning.

👉(Turnkey solutions to maximize sunflower oil yield)

Which processing route suits your sunflower seed project? 🌻

Contact QIE GROUP for a customized sunflower oil production line and technical solution!