Is Investing in a Cooking Oil Processing Plant Expensive? QIE GROUP’s 5 Strategies for Precise Cost Control!

08/20/25

Is investment your primary concern when building a cooking oil manufacturing plant? QIE GROUP (43-year expertise in cooking oil equipment & technology) helps you achieve efficient profitability! 👇

📊 5 Major Investment Factors & QIE Solutions:

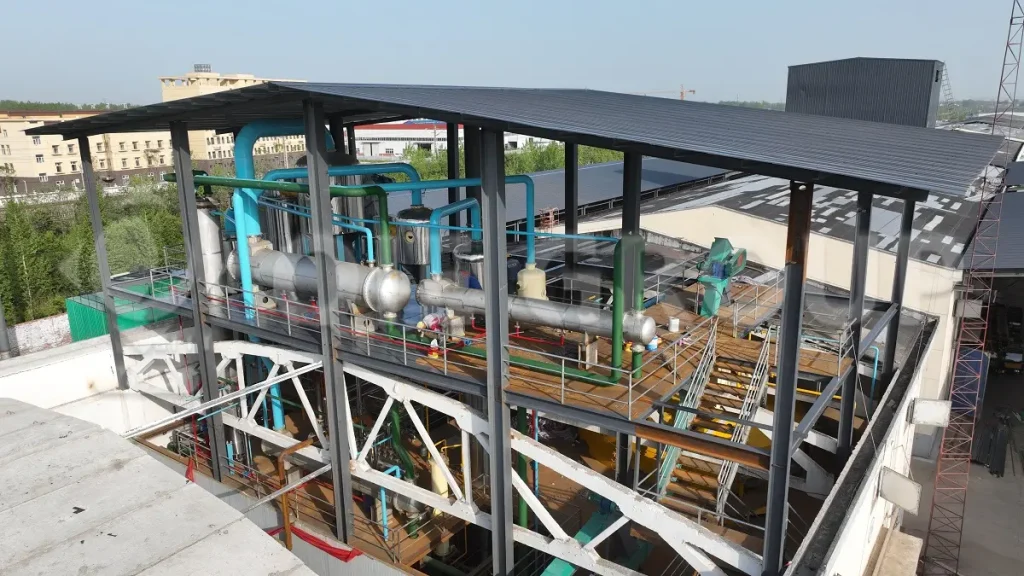

1. Production Scale? 👉 Full range of modular equipment, covering small cooking oil mill plants → large cooking oil refinery plants! Customized solutions eliminate wasteful spending!

2. Equipment Investment? 👉 Full-capacity cooking oil production plant equipment (Pre-treatment/Oil presser/Solvent Extraction Plant/Refinery Plant) ⚡️Energy-efficient, ⚡️Stable & durable. Reduces downtime and energy costs, ensuring high ROI!

3. Raw Material Fluctuations? 👉 Efficient solvent extraction/pressing technology boosts material utilization + oil yield rate, locking in profits! 🌰 Suitable for soybeans, sunflower seeds, peanuts, rice bran, palm kernels,etc.!

4. High Land Costs? 👉 Compact integrated design optimizes process layout + space utilization, directly lowering cooking oil manufacturing plant cost!

5. Rising Labor Costs? 👉 Highly automated cooking oil production line equipment. Simple operation & maintenance slashes labor costs!

✅ Why Choose QIE? China’s leading cooking oil machinery manufacturer & turnkey project service provider!

⚡️ Custom Design: Solutions precisely matched to raw materials, capacity & process needs.

🔝 Core Tech: Material crushing, hot dehulling, extrusion, solvent extraction, bleaching, deodorization, dewaxing. High oil yield + low loss!

🛠️ One-Stop Service: Process design → Equipment manufacturing → Installation → Training & after-sales. Worry-free throughout!

🌍 Global Experience: Successful projects in Russia, South Africa, Indonesia, Pakistan, etc. Adapts to diverse climates, regulations & market demands!

🚀Consult now! Get your own customized cooking oil mill plant investment optimization plan and equipment configuration recommendations!